Industry Application

Product Type

Floor Machines Care: Which Lithium Chemistry is Best?

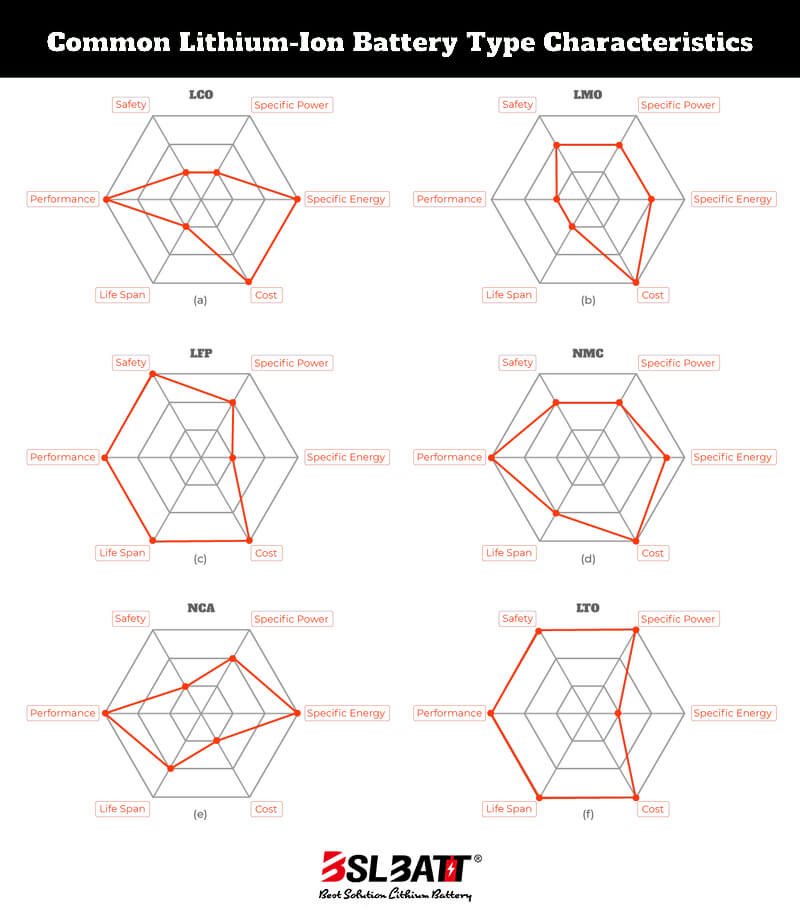

A quick comparison of the strengths of different types of lithium batteries

Though “lithium-ion battery” is typically used as a general, all-encompassing term, there are actually at least a dozen different lithium-based chemistries that make up these rechargeable batteries.

Some of the most common types include:

● Lithium iron phosphate (LFP)

● Lithium nickel manganese cobalt oxide (NMC)

● Lithium cobalt oxide (LCO)

● Lithium manganese oxide (LMO)

● Lithium nickel cobalt aluminum oxide (NCA)

● Lithium titanate (LTO)

In order, we abbreviate them LCO, LMO, NMC, LFP, NCA, and LTO.

However, Commercial Floor Machines is typically powered by either lithium iron phosphate or lithium nickel manganese cobalt oxide chemistries.

Below we’ll explore these chemistries and how they play a role in making lithium-ion batteries one of the most popular choices of power for Commercial Floor Machines.

Lithium Iron Phosphate (LiFePO4)

lithium-ion battery materials lithium iron phosphate is more compact and energy-dense, making it an excellent choice for us in material handling applications, such as powering equipment like electric forklifts, Commercial Floor Machines, and end riders.

Lithium Nickel Manganese Cobalt Oxide (NMC)

Lithium nickel manganese cobalt oxide chemistries are very energy dense, which means they provide a higher level of performance, if the equipment is designed to support it. The high charge and discharge rates make it a more popular choice for electric vehicles, such as e-bikes, buses, cordless power tools and other electric power trains.

Factors to Evaluate

Designers need to understand the trade-offs between these batteries on a range of factors: Energy (Capacity), Power (kW output), Life Span, Cost, and Safety. Some cell types are not a fit for floor care due to life span, cost, or safety concerns. LCO cells have high capacity but are the least safe lithium type—they are often used in mobile phones, laptops, and tablets. LMO cells perform well on most evaluation metrics but have a relatively short life span—they are commonly used in power tools and medical devices. LTO cells are among the safest but their energy capacity is low, and their cost is high—they are typically used in UPSs and street lighting.

Motive Applications

NMC, LFP, and NCA are the most widely used lithium cell types in motive power applications due to their performance on three of the most important factors: Power, Life Span, and Cost. While there are slight differences in their rankings on those factors, designers should evaluate their performance on the other factors more completely.

● LFP is perhaps the most prevalent lithium cell type deployed in floor care today, with a combination of High Power Output, High Life Span, and High Safety—offset by relatively Low Energy Density.

● NMC cells are very balanced in their performance on all five evaluation factors, offering Mid Power Output, Mid/High Life Span, and Mid Safety—delivering Middle-range Energy Density.

● NCA cells are quite similar to NMC, offering slightly less Life Span but increased Energy Density.

Within each cell type, there can be a range of specific commodities included that will lead to slightly different performance on the five evaluation factors. Depending on the combination of various elements (the amount of nickel, cobalt, and aluminum) in each cell type, the energy density and cost may vary. When analyzing battery options for a floor machine, these more specific differences should be considered before a final selection is made.

Floor care machine designers should evaluate the design requirements of their machines and assess each lithium cell type’s strengths against those specific requirements. The energy requirements of one machine may help define the storage capacity that is required and point to one cell type. Life span concerns on another machine may suggest a different cell type. Finally, extreme safety requirements may lead to the selection of another type.

Understanding the trade-offs between popular cell types will help designers make the right lithium choice.

Choose The Right Lithium Battery For Your Job

As you can see, there are many different types of lithium batteries. Each one has pros and cons and various specific applications they excel in. Your application, budget, safety tolerance, and power requirements will determine which lithium battery type is best for you.

A Guide to Choosing the Best 48V Lithium Golf Cart Battery

Would it be worth investing in a 48V ...

10 Exciting Ways To Use Your 12V Lithium Batteries

Back in 2016 when BSLBATT first began designing what would become the first drop-in replacemen...

BSLBATT Battery Company Receives Bulk Orders from North American Customers

BSLBATT®, a China Forklift battery manufacturer specializing in the material handling indust...

Fun Find Friday: BSLBATT Battery is coming to another great LogiMAT 2022

MEET US! VETTER’S EXHIBITION YEAR 2022! LogiMAT in Stuttgart: SMART – SUSTAINABLE – SAF...

Looking for new Distributors and Dealers for BSL Lithium Batteries

BSLBATT battery is a fast-paced, high-growth (200% YoY ) hi-tech company that is leading the a...

BSLBATT to Participate at MODEX 2022 on March 28-31 in Atlanta, GA

BSLBATT is one of the largest developers, manufacturers, and integrators of lithium-ion batter...

What makes the BSLBATT the Superior Lithium Battery for your Motive Power needs?

Electric forklift and Floor Cleaning Machines owners who seek the ultimate performance will fi...