Industry Application

Product Type

IEC 62133 Standard – why is it important for Lithium Solar Batteries?

| Home and industrial energy storage lead to increased demand for lithium-ion safety standards

From 2020 to 2030, the largest demand for lithium-ion batteries will be in the off-grid energy storage market, including the classification of home energy storage systems and industrial energy storage systems (ESS). Lithium batteries present environmental risks and are chemical and electrical hazards when transported or enlarged due to extreme temperature exposure. To address safety standards for lithium-ion battery products, the International Electrotechnical Commission (IEC) 62133- was introduced. BSLBATT’s lithium-ion batteries ensure safety and reliability in the energy storage market.

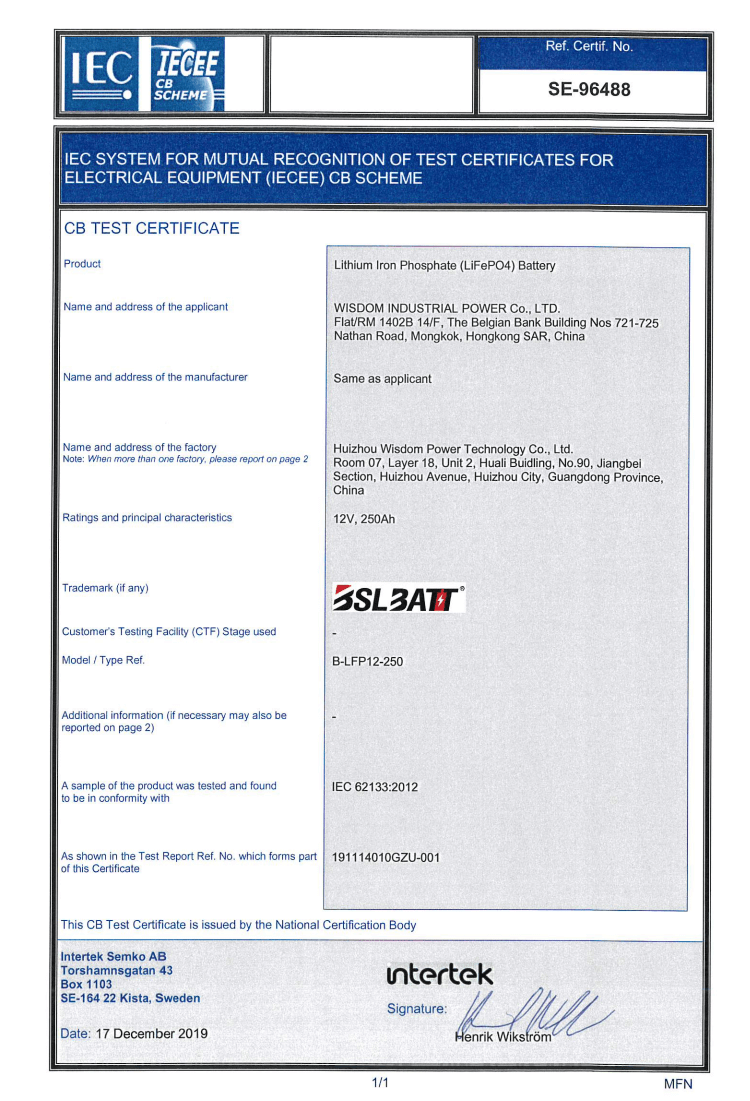

Positioning of BSLBATT BSLBATT is a professional lithium-ion battery manufacturer, including R&D and OEM services for more than 18 years. Our products comply with ISO/CE/UL/UN38.3/ROHS/IEC standards. The company takes the development and production of advanced series “BSLBATT” (best solution lithium battery) as its mission. BSLBATT lithium products power a range of applications, including solar power solutions, microgrids, home energy storage, golf carts, RVs, marine, industrial batteries, and more. The company provides a full range of services and high-quality products, continuing to pave the way for a greener and more efficient future of energy storage.

How to define life expectancy in Lithium solar Batteries systems? Battery manufacturers traditionally define battery life either as float life or cycle life. Float life refers to the number of years it takes the battery to reach the end of its life at an identified reference temperature, usually 25 degrees Celsius. On the other hand, cycle life is the number of times a battery can be cycled (discharged and recharged) before it reaches the end of life. In a float application, the battery acts as a source of backup power. The most common example is the uninterruptible power supply (UPS) system. The AC grid provides the main power, but in the rare situation of a grid failure, the battery provides backup power till power is back from the grid. This means that float applications do not require the battery to be regularly charged and discharged. In technical terms, the battery would not be cycled in a float application. A battery is called cycled when it is frequently charged and discharged. Therefore, in order to define a battery’s life expectancy, the basic assumption is that any specific application can be explicitly seen as either float or cycling. However, renewable energy (RE) applications are a bit different, as Lithium solar Batteries systems are deep-cycling applications. Since neither float life nor cycle life effectively defines the expected life of a battery in a RE application, a different method is needed to identify battery life in Lithium solar Batteries systems. This is where the IEC 62133 standard kicks in. This standard test protocol uses elevated temperature (40°C or 104°F) and a series of cycles that mimic a real-world Lithium solar Batteries systems application. The battery being tested is considered to have reached the end of life when its capacity drops to less than 80% of its rated capacity. About the IEC 62133 Standard IEC 62133 is the most important standard for exporting Lithium-Ion batteries, including those used in IT equipment, tools, laboratory, household, and medical equipment. ● Until 30th April 2011, Secondary (rechargeable) lithium batteries tested to UL 1642 are accepted for CB certification. ● From 1st May 2011, the batteries shall be additionally “gap” tested to parts of IEC 62133. ● From 1st May 2012, the cells and batteries must be fully tested to IEC 62133 for CB certification. The IEC Standard recognizes that batteries in Lithium solar Batteries systems applications take on the characteristics of both float and cycling applications. It also recognizes that they are heavily cycled at PSOC at temperatures higher than 25°C (77°F). Therefore, The IEC 61427 Standard has developed a protocol that simulates a real-life Lithium solar Batteries systems application. The test subjects the battery to a series of shallow DOD cycles under low and high SOC. The IEC Standard assumes that the Lithium solar Batteries are charged during daylight and discharged during the night, with the typical discharge each day consuming between 2% and 20% of the battery’s amp-hour capacity.

TESTING CAPABILITIES IEC 62133 defines the requirements and tests for secondary cells and batteries containing alkaline or other non-acid electrolytes and the batteries made from them. The standard IEC 62133 distinguishes between nickel and lithium-ion cells and batteries. For lithium-ion cells and batteries IEC 62133 contains the following single tests: ● 7.3.1 External Short-Circuit (cell) ● 7.32 External Short -Circuit (battery) ● 7.3.3 Free Fall ● 7.3.4 Crush (cells) ● 7.3.6 Over-Charging of battery ● 7.3.7 Forced Discharge (cells) ● 7.3.8 Mechanical Test (batteries) CONCLUSIONS Predicting battery life expectancy in a Lithium solar Batteries application is difficult because of a variety of unknown factors, which mainly have to do with intermittent weather conditions that influence both the charging and discharging phases. Further complicating the issue, is the tendency to underestimate the battery capacity required to power the loads. A typical Lithium solar Batteries application is mostly cyclic in nature and cannot be accurately classified as either a float application or a true cycling application. Therefore, an alternative method is necessary to determine battery life in a Lithium solar Batteries application. The IEC 62133 Standard offers that method. Because the conditions of the test mimic the following key characteristics of a typical Lithium solar Batteries application, the IEC 62133 Standard is well suited to offer more accurate insights into the life expectancy of a battery in a Lithium solar Batteries application. IEC 62133 test temperature of 40°C (104°F) is warmer than the normal room temperature of 25°C, and therefore more representative of an actual Lithium solar Batteries system installation. Seasonal (winter/summer) cycling accounts for variable charging year-round, which is true for Lithium solar Batteries applications. Partial state of charge (PSOC) cycling allows for batteries to be discharged before they are fully charged, which is a very common occurrence in Lithium solar Batteries applications. When designing a Lithium solar Batteries system and evaluating battery options for use in PV installations, the IEC 62133 standard should be used as the benchmark to compare and contrast the batteries being considered for the application. This ensures an accurate comparison which guarantees that each deep-cycle battery option is tested in exactly the same way. More importantly, since the IEC standard subjects the battery to a set of operating conditions that more accurately resemble the real-world conditions, the results of the IEC 62133 test will provide the best estimate of the battery’s service life in an actual Lithium solar Batteries application. To learn more about the IEC 62133 Standard, visit the IEC website. |

A Guide to Choosing the Best 48V Lithium Golf Cart Battery

Would it be worth investing in a 48V ...

10 Exciting Ways To Use Your 12V Lithium Batteries

Back in 2016 when BSLBATT first began designing what would become the first drop-in replacemen...

BSLBATT Battery Company Receives Bulk Orders from North American Customers

BSLBATT®, a China Forklift battery manufacturer specializing in the material handling indust...

Fun Find Friday: BSLBATT Battery is coming to another great LogiMAT 2022

MEET US! VETTER’S EXHIBITION YEAR 2022! LogiMAT in Stuttgart: SMART – SUSTAINABLE – SAF...

Looking for new Distributors and Dealers for BSL Lithium Batteries

BSLBATT battery is a fast-paced, high-growth (200% YoY ) hi-tech company that is leading the a...

BSLBATT to Participate at MODEX 2022 on March 28-31 in Atlanta, GA

BSLBATT is one of the largest developers, manufacturers, and integrators of lithium-ion batter...

What makes the BSLBATT the Superior Lithium Battery for your Motive Power needs?

Electric forklift and Floor Cleaning Machines owners who seek the ultimate performance will fi...