Industry Application

Product Type

How to PACK a LiFePO4 solar battery bank?

LiFePO4 solar battery bank PACK, also known as battery module, is a lithium-ion battery production process, which means packaging, encapsulation and assembly, refers to connecting multiple lithium-ion single-cell groups in parallel and series, and considering the mechanical strength of the system, thermal management, and BMS matching and other issues. Its important technology is reflected in the overall structural design, welding and processing technology control, protection level, active thermal management system. If two batteries are connected in series or parallel and formed into a specific shape according to the customer’s requirements, it is called a PACK.

The production process of LiFePO4 solar battery bank is divided into two sections: cell module production and system assembly.

If the battery PACK is compared to a human body, the module is the “heart”, which is responsible for the storage and release of electric energy. In the LiFePO4 solar battery bank module production section, the qualified battery cells are assembled into battery modules through the processes of lug cutting, core insertion, lug shaping, laser welding and module packaging;

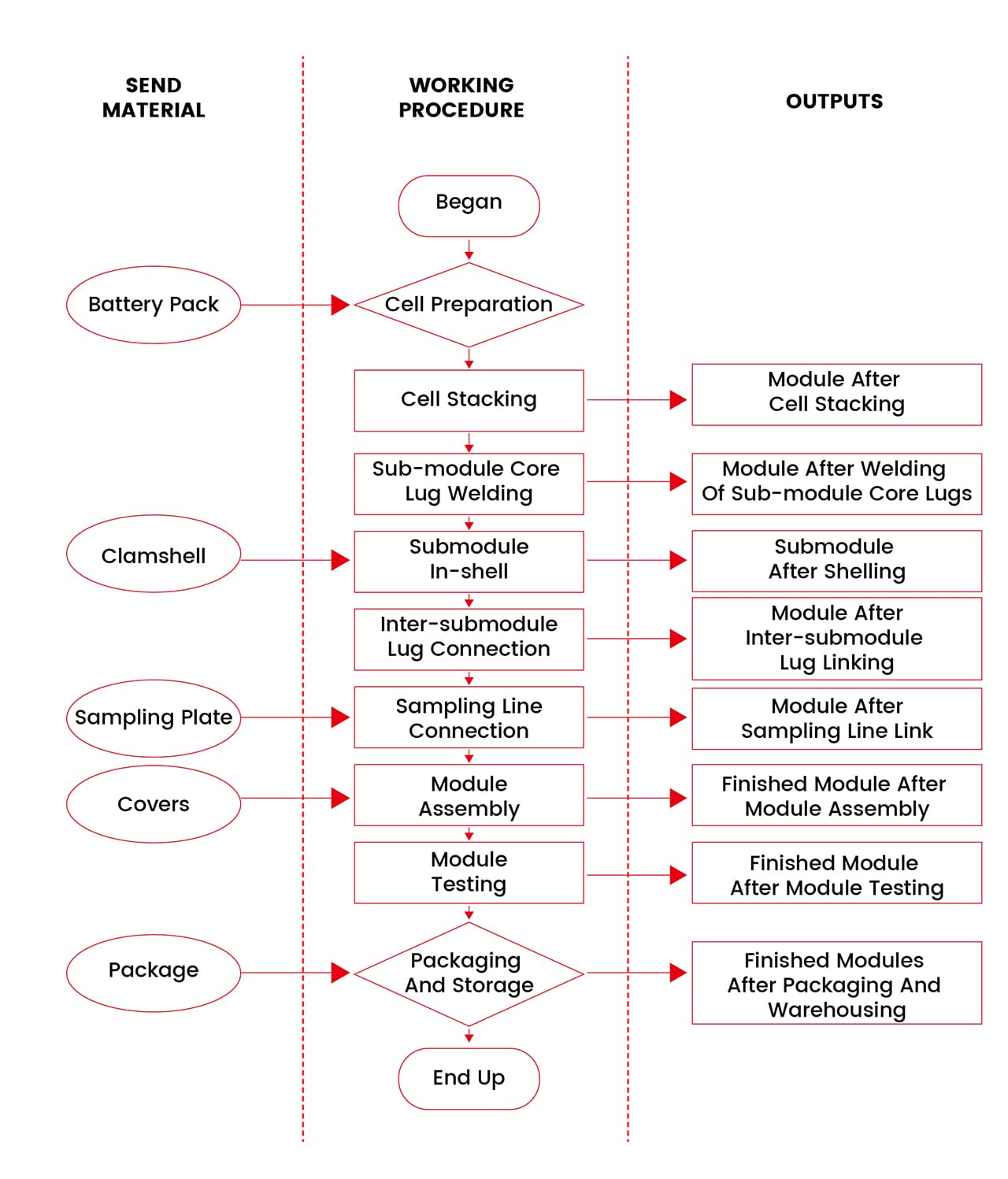

The production process flow diagram of the module is as follows:

(1) Core stacking: this process is the first process of preparing the module. The finished battery cells after passing the test are paired on the line with the components such as side plates, end plates, cover plates and connecting pieces, and then the battery cells are stacked according to a certain series-parallel order.

When stacking, it is necessary to pay attention to the phenomenon of overflowing glue. When stacking the module on both sides of the core needs to be aligned, both sides need to have alignment mechanism, side plane tolerance ≤ 0.5mm. stacking tooling and core contact with the core can not cause damage to the core.

The stacking reference surface of the electric core can be selected according to Party B’s technical level and the range of dimensional tolerance of the electric core (the current tolerance of the drawing of the height of the electric core is 0.5mm), Busbar (hard), but it is necessary to ensure that the horizontal tolerance of the pole surface is ≤0.3mm, and at the same time, there can be no welding defects due to the factor of the Z-direction height difference.

In the process of module stacking, the components and cores are equipped with a positioning mechanism, centered stacking, and each stacked component needs to be shaped and pressed once (length and width), and the whole process prevents short-circuit of the electric core. The appearance of the battery and components should not be damaged, and the blue film of the battery insulation should not be broken.

Before and after stacking, it should be able to judge the polarity of the battery cells in accordance with the series and parallel connection rules of the module. It should be able to alarm when there is an abnormality in the judgment.

(2) Sub-module core lug welding: this process is the second process of preparing modules. The stacked sub-modules are welded onto the reflow channel by laser technology with positive and negative lugs in accordance with the technical requirements; welding of positive lugs to the reflow channel and negative lugs to the reflow channel requires different process parameters.

(3) Sub-module into the shell: this process is the third process of preparing the module. Sub-modules are automatically placed into the shell by robots to form the module.

(4) Connection of lugs between sub-modules: This process is the fourth process in the preparation of the module. Through laser technology, positive and negative lugs are welded onto the reflux tray according to the technical requirements, and the lugs are connected in series between the sub-modules.

(5) Sampling line connection: this process is the fifth process of preparing the module. Through laser technology, the sampling board sampling terminals are welded on the refluxing row according to the technical requirements.

(6) Module assembly: This process is the sixth process of preparing the module. Through the robot will end plate and side plate automatically assembled into the module, through the laser technology, according to the technical requirements to complete the welding.

(7) Module testing: The finished module is tested for its performance, and the qualified finished module is packaged and put into storage after completion.

The module production process mainly consists of sub-module production and assembly of sub-modules into modules, with no by-products.

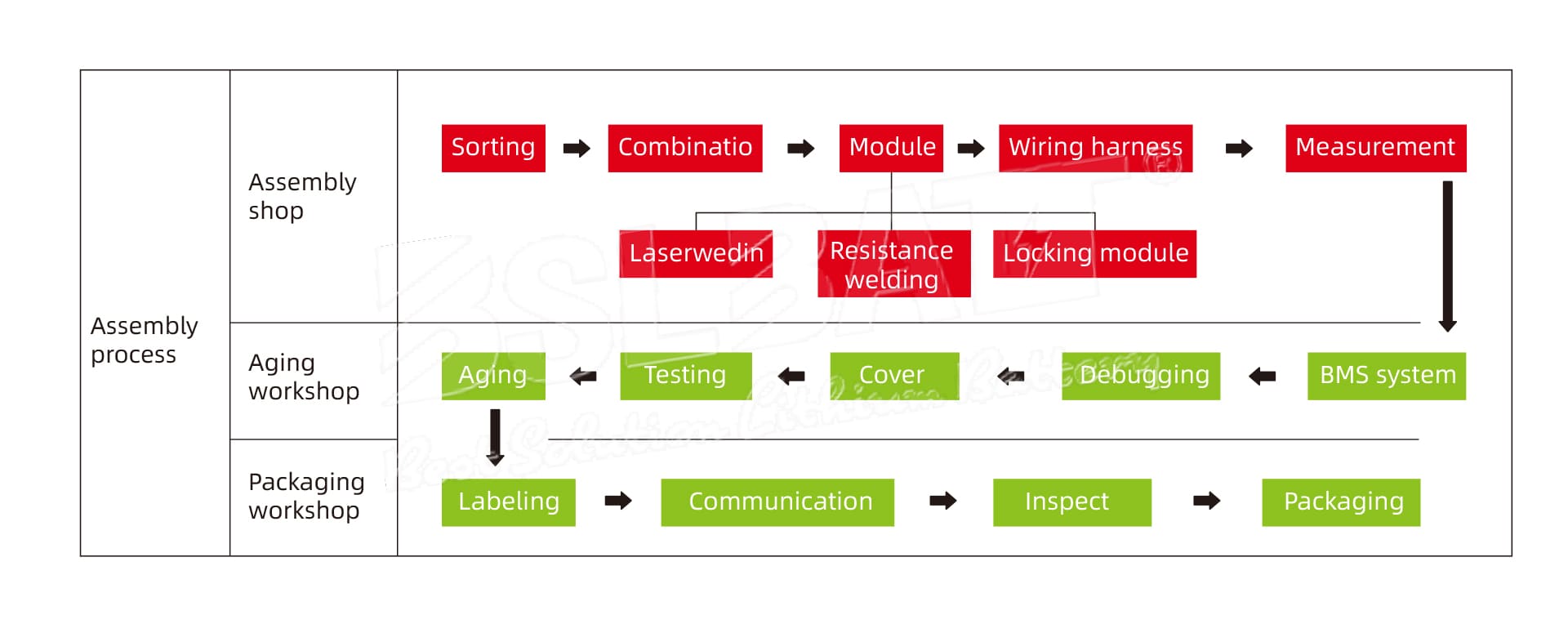

In the LiFePO4 solar battery bank system assembly section: the qualified battery modules and BMS circuit boards are assembled into finished system products, and then enter the finished product packaging section after the primary testing, high temperature aging and secondary testing processes. The details are shown in the figure below:

Characteristics of LiFePO4 solar battery bank PACK

▶ PACK lithium battery banks require a high degree of cell consistency (capacity, internal resistance, voltage, discharge curve, and life).

▶ The cycle life of a battery pack PACK is lower than that of a single cell.

▶ Use under limited conditions (including charging and discharging currents, charging method, temperature, etc.)

▶ The battery voltage and capacity of the lithium battery pack PACK are greatly increased after molding and must be protected and monitored for charge equalization, temperature, voltage, and overcurrent.

▶ Battery PACK must meet the voltage and capacity requirements needed for the design.

LiFePO4 solar battery bank PACK methods

▶ Series-parallel composition: Battery module consists of a single cell connected by parallel and series. The parallel connection increases the capacity and the voltage remains unchanged, while the series connection multiplies the voltage and the capacity remains unchanged.

For example, the voltage of 3.2V cells, 15 in series, is 48V, this is the series boost.

For example the capacity of 50Ah battery cell, two parallel connections, there will be 100Ah, this is the parallel expansion.

▶ LiFePO4 Cell requirements: according to their own design requirements to select the corresponding cell, parallel and series connection of the battery requirements of the same type, the same model, capacity, internal resistance, voltage value difference of not more than 2%. Whether it is a flexible packaging battery or cylindrical battery, it needs to be combined in multiple strings.

▶ Process of PACK: The PACK of the battery is realized through two ways, one is through laser welding or ultrasonic welding or pulse welding, which is the commonly used welding method, the advantage is better reliability, but not easy to replace. The second is through the elastic metal sheet contact, the advantage is that no welding, easy to replace the battery, the disadvantage is that it may lead to poor contact.

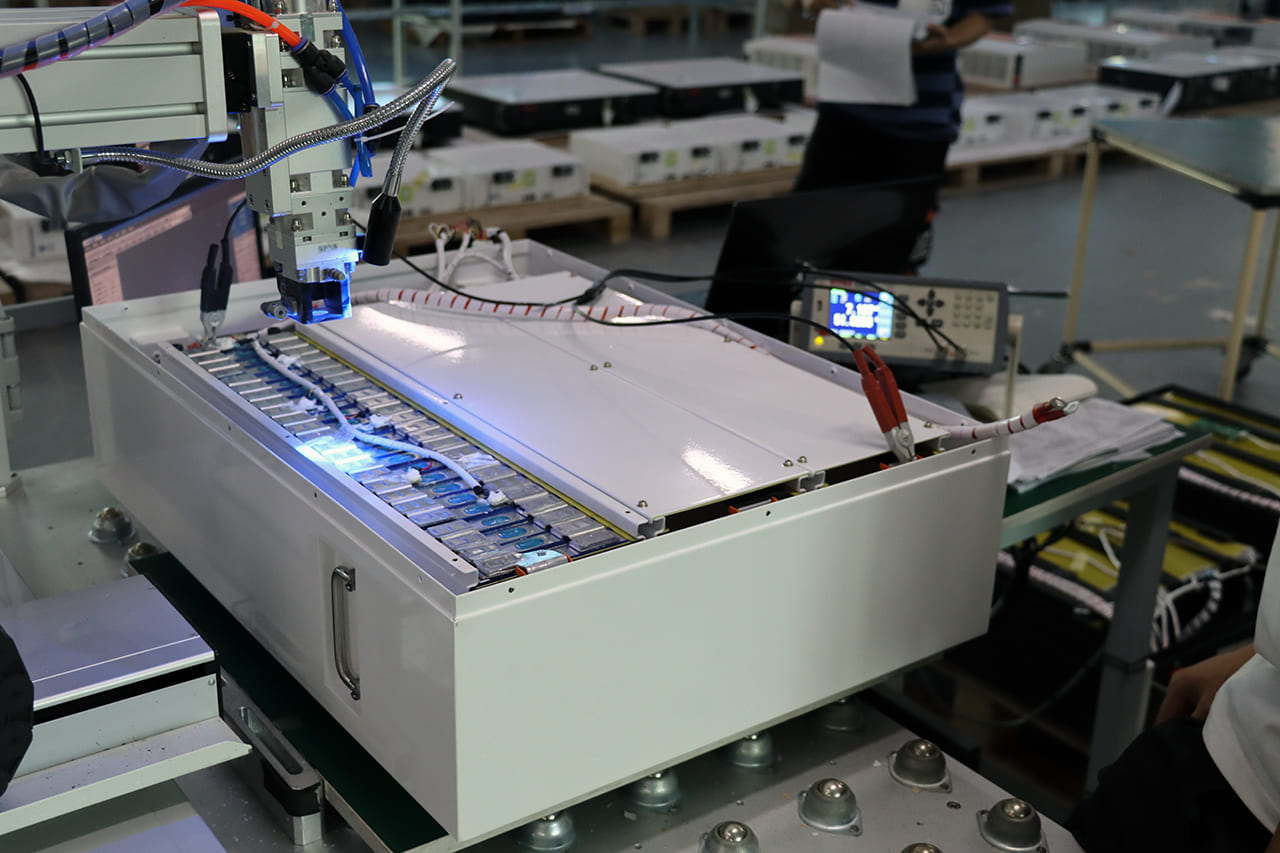

Taking into account the production yield, efficiency and internal resistance of the connection point, laser welding is now the first choice of lithium battery manufacturer BSLBATT.

A Guide to Choosing the Best 48V Lithium Golf Cart Battery

Would it be worth investing in a 48V ...

10 Exciting Ways To Use Your 12V Lithium Batteries

Back in 2016 when BSLBATT first began designing what would become the first drop-in replacemen...

BSLBATT Battery Company Receives Bulk Orders from North American Customers

BSLBATT®, a China Forklift battery manufacturer specializing in the material handling indust...

Fun Find Friday: BSLBATT Battery is coming to another great LogiMAT 2022

MEET US! VETTER’S EXHIBITION YEAR 2022! LogiMAT in Stuttgart: SMART – SUSTAINABLE – SAF...

Looking for new Distributors and Dealers for BSL Lithium Batteries

BSLBATT battery is a fast-paced, high-growth (200% YoY ) hi-tech company that is leading the a...

BSLBATT to Participate at MODEX 2022 on March 28-31 in Atlanta, GA

BSLBATT is one of the largest developers, manufacturers, and integrators of lithium-ion batter...

What makes the BSLBATT the Superior Lithium Battery for your Motive Power needs?

Electric forklift and Floor Cleaning Machines owners who seek the ultimate performance will fi...