- China

- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

Industry Application

Product Type

LiFePO4 And The Environment

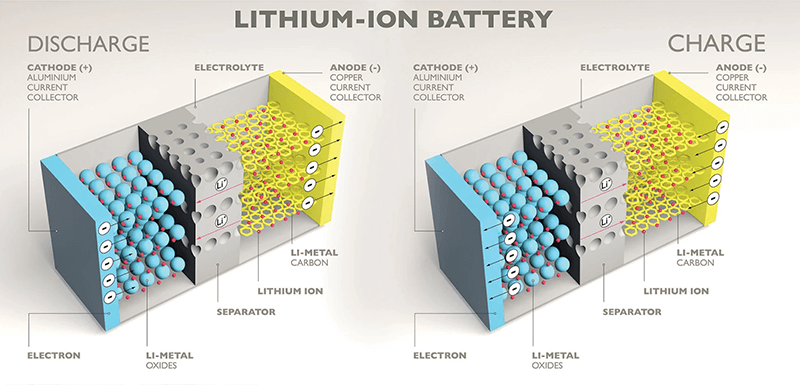

| One of the most common complaints about the accelerating push for mass electrification of transport and industry is that there’s no means to handle the tremendous volume of waste batteries that will be generated. But what if there was a technology that could readily recycle all that waste without generating the pollution in the process? What if someone could economically recover not only the high-value metals like nickel and cobalt but the lower-value components too?

Did you know that LiFePO4 batteries use no rare earth or toxic metals? They utilize commonly available materials including copper, iron, and graphite. In honor of Earth Day, in this week’s blog, we’re sharing a few reasons why lithium iron phosphate batteries are better for the environment. LiFePO4 batteries have many features that make them superior to other battery technologies. They’re lightweight and versatile. They have a long lifespan and a fast recharge rate. They can withstand cold, heat, collision, and mishandling without risk of combustion. And there are big environmental advantages to using LiFePo4 batteries over lead-acid. But how do LiFePO4 batteries stack up against other types of lithium batteries in terms of environmental friendliness?

Quite well, it turns out.Lithium itself is not toxic and it does not bioaccumulate like lead or other heavy metals. But most lithium battery chemistries use oxides of nickel, cobalt, or manganese in their electrodes. Estimates suggest it takes 50% more energy to produce these materials compared to the electrodes in LiFePO4 batteries. They have big advantages over other lithium chemistries:They use no rare earth or toxic metals and employ commonly available materials including copper, iron, and graphite Less energy is consumed in the mining and processing of materials Phosphate salts are also less soluble than metal oxides, so they are less likely to leach into the environment if the battery is improperly discarded And of course, LiFePO4 batteries are chemically stable against combustion and rupture under nearly all operating and storage conditions Once again, lithium iron phosphate batteries come out ahead.We’re all concerned about protecting the environment, and we strive to do our part to reduce pollution and resource consumption. When it comes to choosing a battery technology, LiFePO4 batteries are an excellent choice for enabling renewable energy like wind and solar and for minimizing the consequences of resource extraction.

A number of valuable metals and substances can be extracted from used batteries. This is performed by recycling professionals who meet the same high standards as the rest of the industry and this process is covered by specific legislation. These materials are reused either in new batteries or other industries. Thousands of tons of metals such as silver, cobalt, nickel, and lead can be recovered for these purposes. This ensures environmentally sustainable and responsible production of these materials which are often scarce. For example, the lead used in lead-based batteries operates in a closed-loop, with 99.5% of a battery’s lead being recoverable and can be used in new batteries. Other battery components are likewise recycled, either being used in the production of new batteries or by other industries (Sodium Nickel Chloride batteries’ waste can be used in existing industries such as in the production of stainless steel and road pavement, for example). End-of-life batteries’ materials are often extracted by battery manufacturers or their subsidiaries which allows them to safely feedback into the battery production process directly. Numerous safeguards exist to ensure that waste from batteries is properly controlled. Legislation, industry standards, and guidelines dictate how used automotive and industrial batteries are handled and their waste carefully dealt with. These high standards follow batteries through their life cycle to ensure that there is minimal impact on the environment with the entire supply chain regulated to maintain strict controls. Particular care is taken when batteries reach the end of their life when they are disposed of in a safe manner by disposal experts. For more information on legislation concerning waste, batteries see the section on EU Policy or visit the European Commission’s page on waste batteries, http://ec.europa.eu/environment/waste/batteries/index.html. Reference source: Association of European Automotive and Industrial Battery Manufacturers |

A Guide to Choosing the Best 48V Lithium Golf Cart Battery

Would it be worth investing in a 48V ...

10 Exciting Ways To Use Your 12V Lithium Batteries

Back in 2016 when BSLBATT first began designing what would become the first drop-in replacemen...

BSLBATT Battery Company Receives Bulk Orders from North American Customers

BSLBATT®, a China Forklift battery manufacturer specializing in the material handling indust...

Fun Find Friday: BSLBATT Battery is coming to another great LogiMAT 2022

MEET US! VETTER’S EXHIBITION YEAR 2022! LogiMAT in Stuttgart: SMART – SUSTAINABLE – SAF...

Looking for new Distributors and Dealers for BSL Lithium Batteries

BSLBATT battery is a fast-paced, high-growth (200% YoY ) hi-tech company that is leading the a...

BSLBATT to Participate at MODEX 2022 on March 28-31 in Atlanta, GA

BSLBATT is one of the largest developers, manufacturers, and integrators of lithium-ion batter...

What makes the BSLBATT the Superior Lithium Battery for your Motive Power needs?

Electric forklift and Floor Cleaning Machines owners who seek the ultimate performance will fi...