- China

- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

Industry Application

Product Type

Lithium Forklift Battery vs. Lead Acid Battery: Cost-Saving Industry Game-Changer

| New lithium batteries make electric forklifts an even more viable alternative to diesel vehicles.

Electric forklifts have been around for years, but some recent developments with both battery technology and an introduction of more powerful forklifts have made the industry more receptive to the idea of switching over. The lithium-ion forklift battery is poised to revolutionize the materials handling industry. And when you compare the pros and cons of the lithium battery vs. lead-acid battery for powering your forklift or fleet of lift trucks, it is easy to understand why. The biggest reason is that the potential cost savings are enormous. It’s true that lithium forklift batteries do cost considerably more than lead-acid batteries, but they last 2-3 times longer and create dramatic savings in other areas that guarantee you a significantly lower total cost of ownership. “Major companies in big industries, such as the automotive industry, are driving the development in part because of environmental policies and directives they are required to follow. In response, smaller companies are also switching to electric trucks, even though the development is driven by the major players in different industries,” says Bella Chen, Business Development Manager BSLBATT Forklift trucks.

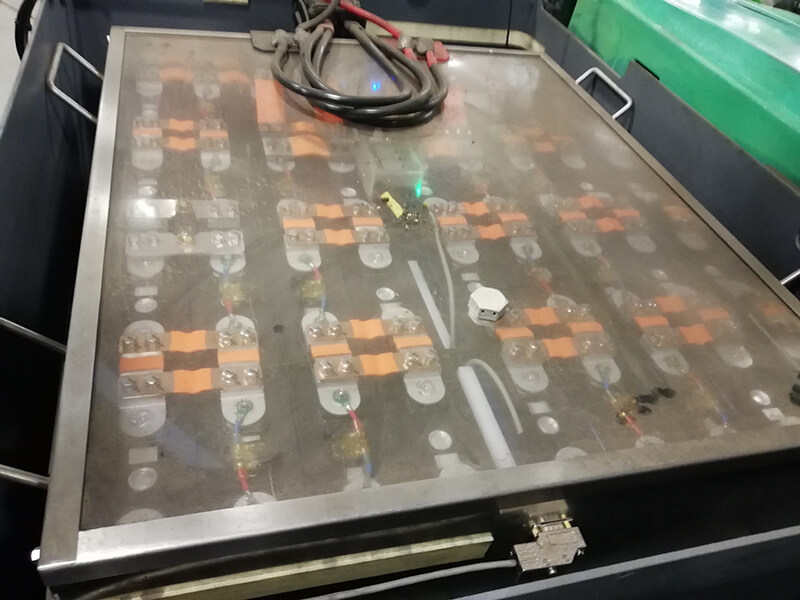

The Ideal Solution for Every ApplicationThe use of Li-ION batteries is suitable for all applications. However, their advantages are particularly useful in intensive applications such as multi-shift operation and refrigerated storage. Due to the elimination of emissions and possible impurities in lead-acid batteries, the technology is also particularly suitable for use in areas where a high degree of sensitivity is required, for instance, the pharmaceutical or food industry. For companies looking for an alternative to their internal combustion forklift fleet, Li-ION batteries are an environmentally friendly option. Here are some of the key advantages that make powering your electric lift trucks with lithium batteries a smart decision: The average price for a lithium-ion forklift battery is roughly $17-20k (about 2-2.5x more than a similar lead-acid battery). For that higher upfront price, an operation will save money on: ● Energy bills: lithium-ion batteries are 30% more energy-efficient and charge 8x faster than lead-acid batteries ● Batteries: your lithium-ion battery will last 2-4x longer than a lead-acid battery ● Downtime: lithium-ion batteries never need to be swapped out and can be opportunity-charged during operator breaks ● Labor costs: lithium-ion forklift batteries do not require maintenance or watering ● Productivity: enjoy longer run-times and no decline in performance as the battery discharges ● Hazards: li-ion batteries don’t emit harmful fumes or CO2, there’s no risk of acid spills, and you’ll have 70-80 percent fewer batteries to dispose of overtime because you won’t be replacing batteries as often. ● Real estate: reclaim the area you’re using as a charging room for additional storage ● Less downtime ● Longer warranties ● Safer operations How long does a lithium-ion battery take to charge?Li-ion batteries can charge throughout the day in 15 or 30 min spurts, or fully charge during a one to two-hour continuous session. Compare this to the eight hour charge time plus an additional eight-hour cool downtime for a lead-acid battery. How much runtime will I get from a lithium-ion battery?As with lead-acid batteries, the runtime depends on the application (how much lifting, how much uphill travel). Generally speaking, a lithium-ion battery will last as long as a lead-acid battery – but it charges faster and does not cause a decline in performance as it discharges.

Can a forklift be retro-fitted to use a Lithium-ion battery?Yes! Conversion is quick and easy. The retro-fit simply requires installing the new battery and adding the charge meter. Great endurance, minimal maintenanceCompared to the old technology, the new Li-ion battery has several benefits. One, there’s no need to have several batteries in multi-shift operation, one is enough because it can be recharged during the shift. Two, the new battery lasts for up to 4,000 cycles, compared to lead-acid battery’s 1,500 cycles. “The battery efficiency is 95 percent, compared to 70 with the lead-acid battery. Also, there’s minimal maintenance,” Malmström continues. “All in all, compared to diesel trucks, electric machines need less maintenance because there are fewer components that need service or have to be exchanged,” adds Johansson. The new lithium-ion battery lasts longer and requires less maintenance, but as with all new technologies, there is a cost, too. And it’s just that: cost. “It’s true that the prices are fairly high at the beginning, but we’ve seen that they tend to come down quickly as the technologies mature,” Bella Chen says. “We should also keep in mind that the chemistry is complicated and that the technology the automotive industry chooses will also go down in price fast, thanks to their sheer volumes. In a couple of years, the lithium battery will be much more cost-efficient than lead-acid batteries,” he adds. Worth noting about the Lithium-ion batteries is that there is a residual value to take into account, a used battery for one player will be a valuable battery for another one. A driver’s dreamFactoring in the fuel savings and the battery’s life-cycle costs, the deal gets better, Eric Yi notes and adds another benefit the electric trucks have. And it’s one that is most noticeable to the people actually driving them. “The electric trucks are silent, there’s no noise. There are no vibrations when the truck is idling. There are no exhaust gases. The trucks are faster and have better acceleration. On short distances, an electric truck is more effective than a diesel truck,” he lists. Lead Acid Battery vs. Lithium BatteryBSLBATT’s Li-ion battery• Last for 2,400-4,000 cycles • Battery efficiency 95% • Charging time: 1% per minute, fully charged in 100 minutes • Is charged in-situ • Does not require a ventilated space • Requires minimal maintenance • It can be an opportunity charged for multi-shift operation. • Potential power in the grid: ECG50-90: 3-phase, 400 V; 2×32 A fuse

Wisdom Power’s Lead-acid battery• Last for 1,200 to 1,400 cycles • Battery efficiency 70% • Charging time: 8 hours • Generally removed to be fully charged • Requires a ventilated charging space • Requires some regular maintenance • Additional batteries required for multi-shift operation. • Potential power in the grid: ECG50-90: 3-phase, 400 V; 63 A fuse ECG90-180: 3-phase 400 V; 2×63 A fuse Even though lithium-ion batteries cost more upfront, they can quickly pay for themselves through reduced operating costs – offering some businesses a long-term competitive advantage. For more information about whether making the switch to lithium-ion might be a smart investment for your operation, contact one of our forklift battery experts online or by phone. |

A Guide to Choosing the Best 48V Lithium Golf Cart Battery

Would it be worth investing in a 48V ...

10 Exciting Ways To Use Your 12V Lithium Batteries

Back in 2016 when BSLBATT first began designing what would become the first drop-in replacemen...

BSLBATT Battery Company Receives Bulk Orders from North American Customers

BSLBATT®, a China Forklift battery manufacturer specializing in the material handling indust...

Fun Find Friday: BSLBATT Battery is coming to another great LogiMAT 2022

MEET US! VETTER’S EXHIBITION YEAR 2022! LogiMAT in Stuttgart: SMART – SUSTAINABLE – SAF...

Looking for new Distributors and Dealers for BSL Lithium Batteries

BSLBATT battery is a fast-paced, high-growth (200% YoY ) hi-tech company that is leading the a...

BSLBATT to Participate at MODEX 2022 on March 28-31 in Atlanta, GA

BSLBATT is one of the largest developers, manufacturers, and integrators of lithium-ion batter...

What makes the BSLBATT the Superior Lithium Battery for your Motive Power needs?

Electric forklift and Floor Cleaning Machines owners who seek the ultimate performance will fi...