- China

- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

Industry Application

Product Type

Lithium-ion Battery Prices fall nearly 50% in 3 years, spurring more electrification

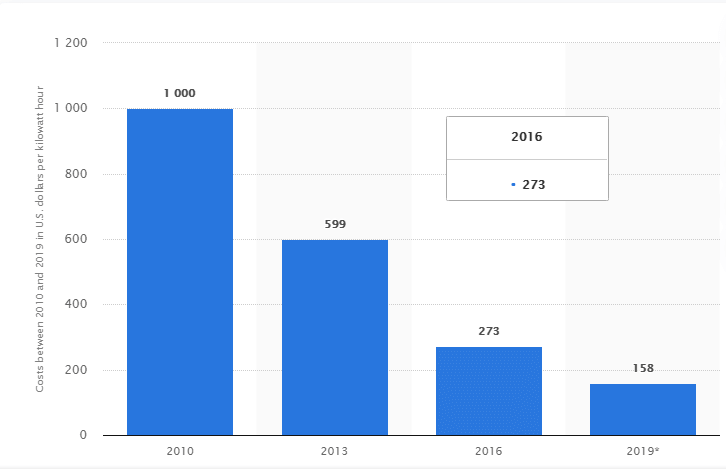

| The price of lithium-ion batteries has plummeted over the past decade. Battery pack prices averaged $1,160 per kWh in 2010, consistent with BloombergNEF, but they dropped to $176 per kWh last year, and experts suggest they might be but $100 by 2024.

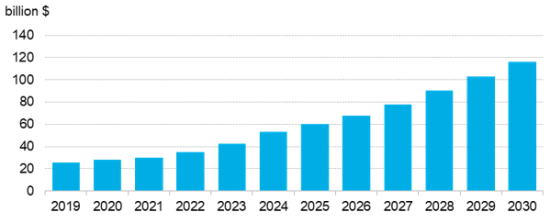

While the elemental components of the LIB have remained similar, continuous development and diversification of the technology means we’ve seen significant performance gains in Li-ion performance, though not as fast as is probably necessary or desired. Performance improvements are still required to enhance range, cost, and a recharge time of battery electric vehicles (BEVs) and various avenues are being pursued. BNEF’s 2019 Battery Price Survey, published at the BNEF Summit in Shanghai, predicts that as cumulative demand passes 2 TWh in 2024, prices will fall below $100/kWh. This price is seen because of the point around which EVs will start to succeed in price parity with combustion engine vehicles. However, this varies counting on the region of sale and vehicle segment. The report further examines intimately how manufacturers and automakers alike can still reduce prices. According to our forecasts, by 2030 the battery market is going to be worth $116 billion annually, and this doesn’t include investment within the supply chain. However, as cell and pack prices are falling, purchasers will get more value for his or her money than they are doing today. —James Frith, BNEF’s senior energy storage analyst and author of the report Annual lithium-ion battery market size. Source: BloombergNEF BNEF’s analysis finds that as batteries become cheaper, more sectors are electrifying. for instance, the electrification of economic vehicles, like delivery vans, is becoming increasingly attractive. this may cause further differentiation in cell specifications, with commercial and high-end passenger vehicle applications likely to choose metrics like cycle life over continued price declines. However, for mass-market passenger EVs, low battery prices will remain the foremost critical goal. Continued cost declines for batteries within the 2020s are going to be achieved through reduced manufacturing capital expenditures, new pack designs, and changing supply chains. “Basically, the assembly capabilities—the production process—I think that’s the amount one driver in bringing down the value of lithium [batteries], the economics of scale. the opposite thing though, it’s not just the assembly, it’s also the method of getting the raw materials. So, the assembly process of mining, the assembly process of refining those minerals, then also, of course, the assembly process of creating the cell, even to creating the battery pack. I mean, all of those processes are being refined,” Cooper said. “And the quality’s there because it’s all highly automated—everything is precision measured—so, nowadays, you’ve got an excellent quality of cells beginning at an enormous rate,” Cooper added. Although Cooper suggested it’s getting harder and harder to optimize the assembly process for battery cells, he said there’s still room for improvement in systems. “There are many things which will be done to stay improving from a system-level efficiency,” he said. Repurposing lithium battery packs offers value for the facility grid. Although electric vehicle (EV) battery packs reach some extent during which they’re not suitable to be used in cars, the packs still have an excellent capacity for purposes during which space isn’t a limitation. Mercedes-Benz Energy, for instance, has incorporated EV battery packs into the electrical grid at several sites. Lithium-ion battery pack costs worldwide between 2010 and 2019

BNEF says that the trail to achieving $100/kWh by 2024 looks promising, albeit there’ll undoubtedly be hiccups along the way. there’s much less certainty on how the industry will reduce prices even further, from $100/kWh right down to $61/kWh by 2030—not because it’s impossible but rather that there is a spread of options and paths which will be taken. “Second life may be a huge thing for lithium,” Cooper said. “With lithium, you’ve got a really good end of life or cycle life, where it’s very linear. It doesn’t have a waterfall, where just all of a sudden it stops working like lead-acid. It’ll really be very linear. So, a pack that has 50% capacity features a lot of energy which will be put into applications that don’t require small spaces or have room for them.” The benefits of lithium-ion over lead-acid batteries are quite significant, too. Cooper noted that one of the most important benefits revolves around maintenance. Lithium-ion batteries require zero maintenance. “And we actually mean zero maintenance,” Cooper said. “Lithium batteries take no special side operations. No one’s needed there to tighten bars down, water, or anything like that. It’s really zero maintenance, so it’s an enormous benefit.” Another benefit is energy savings. Cooper said charging lithium-ion batteries can save 20% or more compared to lead-acid, and there’s also greater efficiency during discharge. Lithium technology performs better in cold-temperature operations. Cooper said lead-acid batteries can lose up to 50% of their capacity when temperatures drop to freezing and below, while lithium still operates well. Furthermore, heaters are often effectively placed on lithium-ion batteries, as there’s less mass to warm. Another drawback of lead-acid batteries is that they will leak acid and release hydrogen gas, whereas lithium designs are sealed and clean. As we meet up with to the last half of the 2020s energy density at the cell and pack level will play a growing role, BNEF says, because it allows for more efficient use of materials and manufacturing capacity. New technologies like silicon or lithium anodes, solid-state cells, and new cathode materials are going to be key to helping cost reductions play out. |

A Guide to Choosing the Best 48V Lithium Golf Cart Battery

Would it be worth investing in a 48V ...

10 Exciting Ways To Use Your 12V Lithium Batteries

Back in 2016 when BSLBATT first began designing what would become the first drop-in replacemen...

BSLBATT Battery Company Receives Bulk Orders from North American Customers

BSLBATT®, a China Forklift battery manufacturer specializing in the material handling indust...

Fun Find Friday: BSLBATT Battery is coming to another great LogiMAT 2022

MEET US! VETTER’S EXHIBITION YEAR 2022! LogiMAT in Stuttgart: SMART – SUSTAINABLE – SAF...

Looking for new Distributors and Dealers for BSL Lithium Batteries

BSLBATT battery is a fast-paced, high-growth (200% YoY ) hi-tech company that is leading the a...

BSLBATT to Participate at MODEX 2022 on March 28-31 in Atlanta, GA

BSLBATT is one of the largest developers, manufacturers, and integrators of lithium-ion batter...

What makes the BSLBATT the Superior Lithium Battery for your Motive Power needs?

Electric forklift and Floor Cleaning Machines owners who seek the ultimate performance will fi...